Air showers

Standard and customised air showers for your processes

Manifacturing flexibility

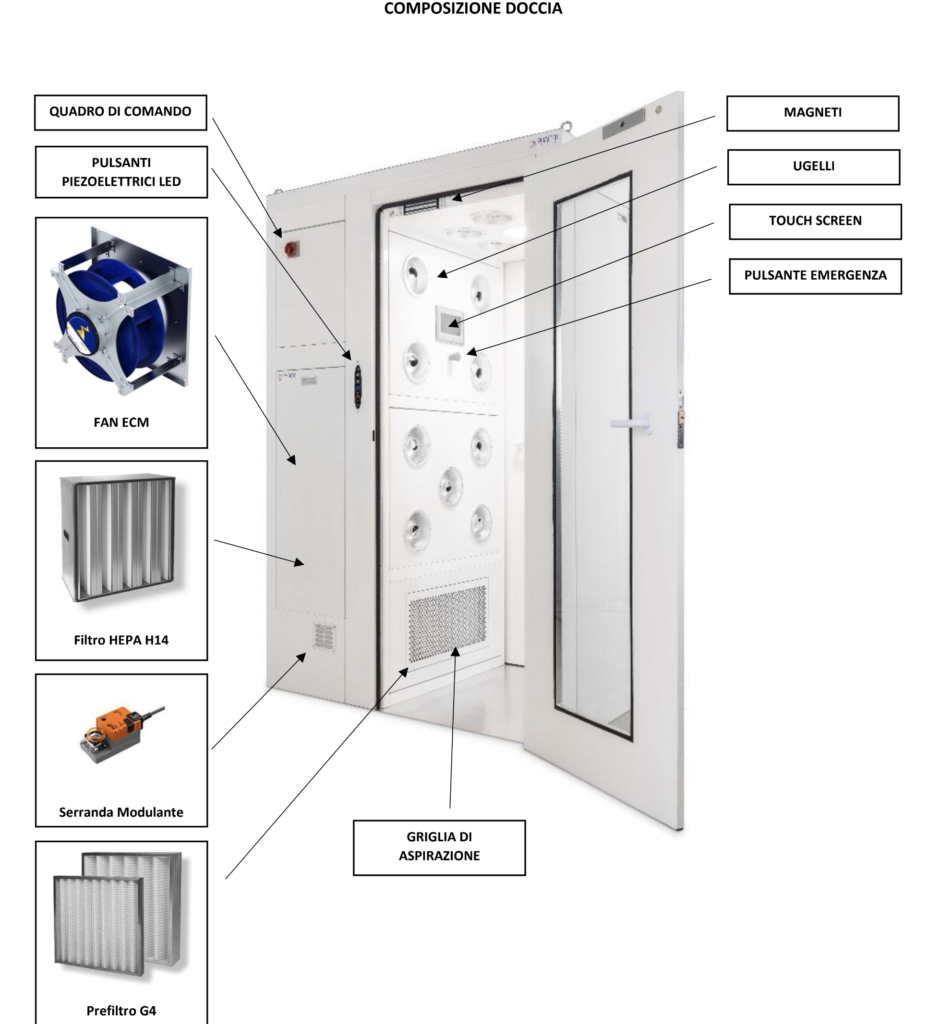

A prerogative of controlled contamination environments is the control and management of contaminants. Contaminants must not be spread inside, or outside in the case of harmful dust, of the controlled areas. A very effective method is to equip such environments with special machines, called ‘air showers’, that can remove any fibres or dust deposited on the clothing of personnel entering or leaving two environments. This removal is done by means of air showers. Each air shower consists of high-pressure nozzles evenly distributed over the shower’s inner surface. A high-capacity air stream, pre-filtered by HEPA filters, is able, through contact with the garment, to detach particles from the operator. The contaminated air is taken back into the base of the shower by special grilles so that it can be filtered again and put back into circulation.

Our

products

Password

Phamm Engineering’s great production flexibility makes it possible to produce non-standard models according to customer specifications.

Cleanroom application:

the greatest source of contaminants in controlled environments is the operator. The adoption of such machinery renders this contamination almost nil.

Pharmaceutical and research application:

showers have the ability to keep pharmaceutical products in a contamination-free state and, above all, to prevent the spread of hazardous substances outside a given area.

MAIN FEATURES:

- SIEMENS control system manageable and configurable via TCP-IP

- 8″ colour TOUCH PANEL and Siemens PLC for setting “wash” times

- HEPA filter with >99.99% efficiency for 0.3 micron particles

- Pre-filter with 85% efficiency placed before the HEPA filter

- Manual emergency door release button

- Full height glass doors equipped with automatic door closer

- Interlocked doors complete with entry semaphores and controlled by PLC

- Automatic door release in the event of a power failure

- High-efficiency IE4 fans with integrated inverter

- Internal nozzles made of aluminium, complete with high throw damper greater than 20 m/s

- Programmable overpressure control automatically adjusted by PLC

- Signalling of dirty filters and remaining service life (estimated)

- LED lamp

- Construction in powder-coated carbon steel RAL 9010, on request in stainless steel 304 or 316

- Construction with non-standard dimensions possible

Get in touch for more information!

Diverse soluzioni

per diversi Settori

Phamm Engineering services

Phamm Engineering stands out for the efficiency and completeness of services for clean rooms: from consultancy and plant design to qualified assistance and maintenance support.

Stay updated:

what you need to know.

Highlights to explore for your company.